Trimmer

Can Making Machinery

Trimmer

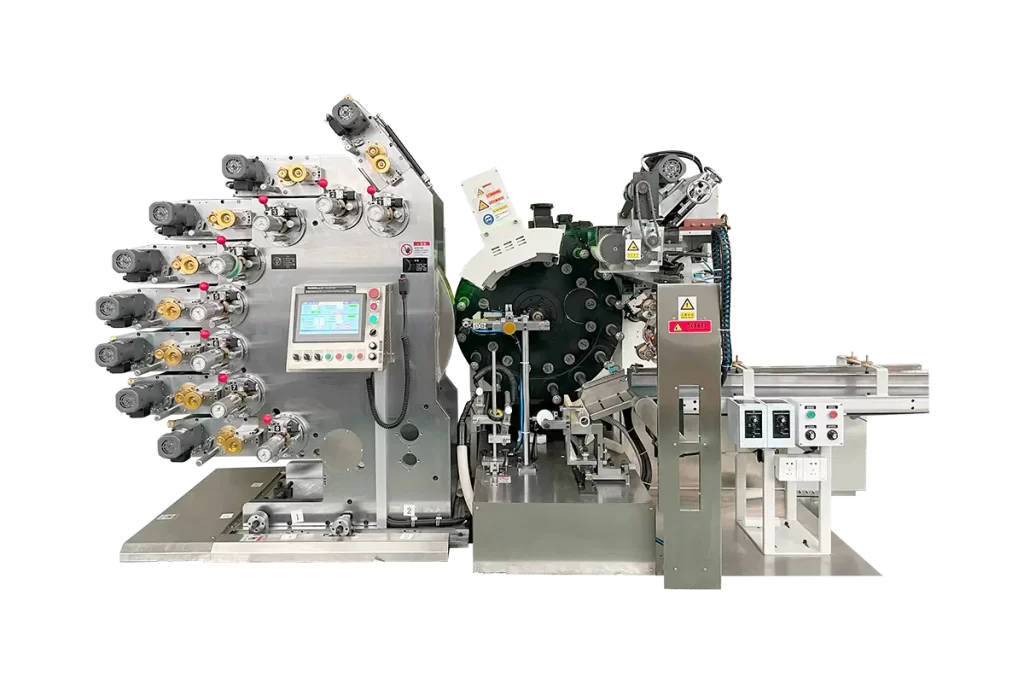

Woolley Rotary Trimmers, in production since 2013, reduce downtime and ensure burr-free, sliver-free, step-free trimming.

Can Making Machinery

Key Benefits

With over 12 years of proven reliability, the Woolley Trimmer is the premier choice for canmakers worldwide for precisely trimming the raw edge of the can caused by the drawing and ironing process from the Bodymaker. Producing burr-free, sliver-free, and step-free trimming, the Woolley Trimmer ensures the highest quality of product.

At Woolley, we understand the importance of efficiency and integration. That’s why our Trimmer is equipped with a sliding base feature, allowing for quick adjustments of the infeed track location and easy integration with the Bodymaker. The Trimmer is available in two series, continuously operating at speeds up to 400 cpm and 500 cpm, respectively.

Can Making Machinery

Features

‣ Easy Maintenance Cartridges

‣ Vacuum Grease Trap

‣ Infeed Overload Clutch

‣ Stainless Steel Guarding

‣ Constant Velocity Infeed

‣ Automatic Lubrication

‣ Sliding Base Option

‣ Available in Three Can Flow Configurations

‣ Option of Inside or Outside Burr

‣ Variable Speed Capable

‣ Extended Legs (If Required)

Can Making Machinery

Introduce

The Trimmer series was designed with customers at the forefront of our focus. This series features two models, which reposition the discharge location in respect to the infeed. The RML style is perfect for customers who need the preformed cans to enter and exit on the same side of the Trimmer. On the other hand, the style is ideal when space is a limiting factor, with the infeed and discharge on opposite sides of the machine.

Our Trimmer series is perfect for operations with minimal changeovers. With speeds up to 500 cpm, this model is achieved by the addition of two more cartridges.

Can Making Machinery

Related Products

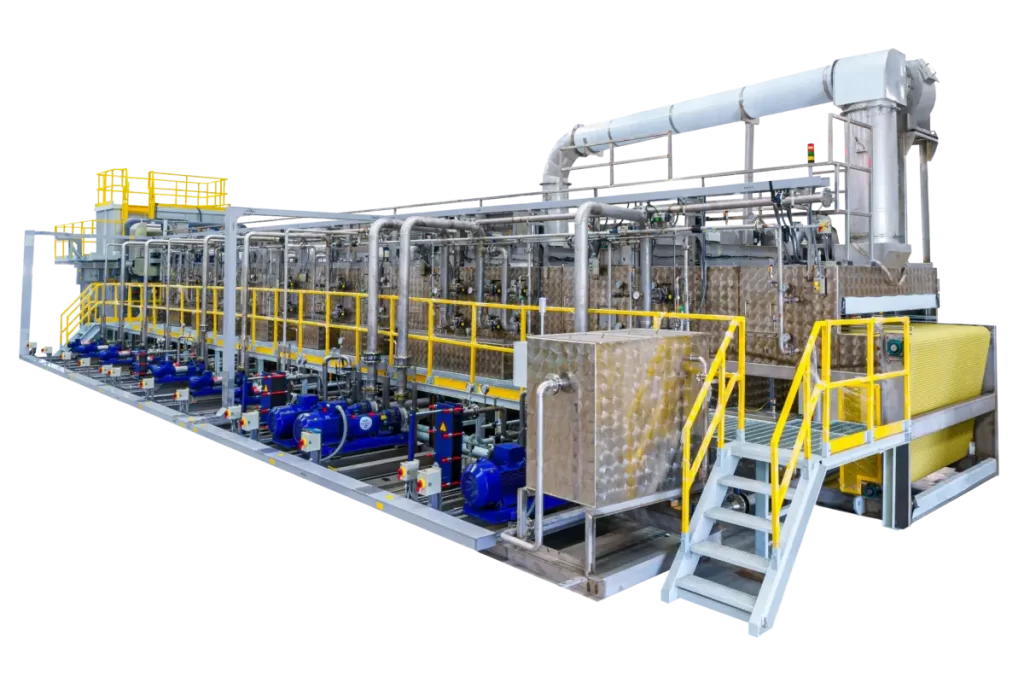

Engineered for energy efficiency, wastewater reduction and process optimization, the ARC Pacific Can Washer operates up to 6,000 cpm.

Dry-off Oven is designed for high efficiency with VFD fans, dynamic oven balance based on production conditions and premium insulation technology.

The Woolley Decorator produces high quality printed cans efficiently with continuous operating speeds up to 2,200 cpm.

Need Help?

Ready to speak with a Woolley team member? Contact us today.

contact us