Machinery

Can Making Machinery

Machinery

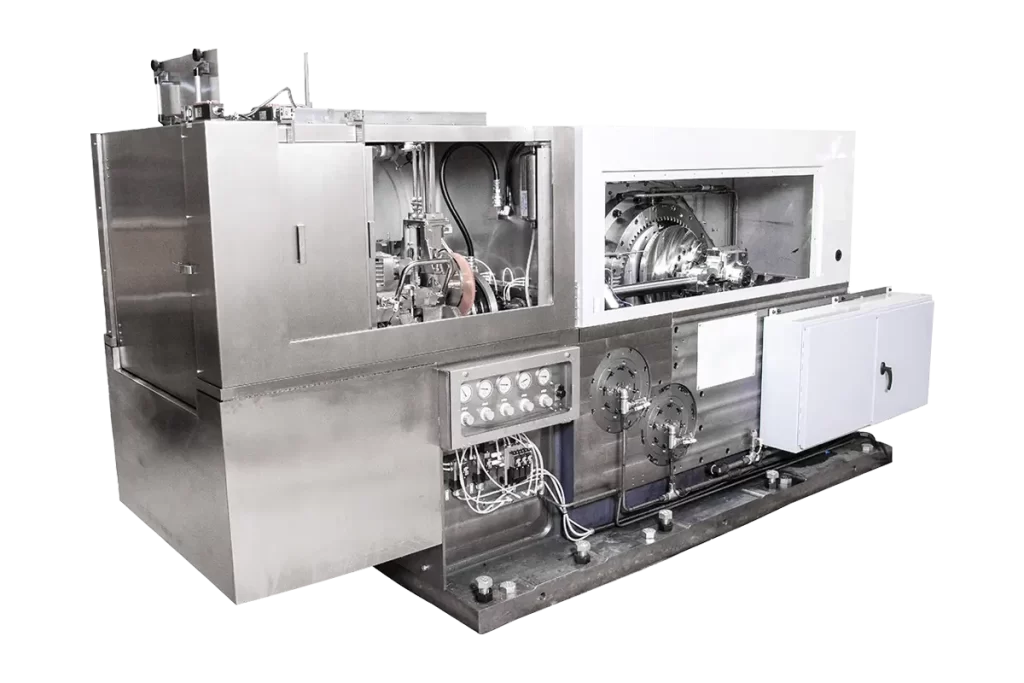

The Woolley Cupping Press features high process reliability, high output, and unsurpassed quality, continuously operating up to 300 spm.

Utilizing a hypocycloid main drive the Woolley Bodymaker produces superior can quality with low tear-off rates, continuously operating up to 400 cpm

Woolley Rotary Trimmers, in production since 2013, reduce downtime and ensure burr-free, sliver-free, step-free trimming

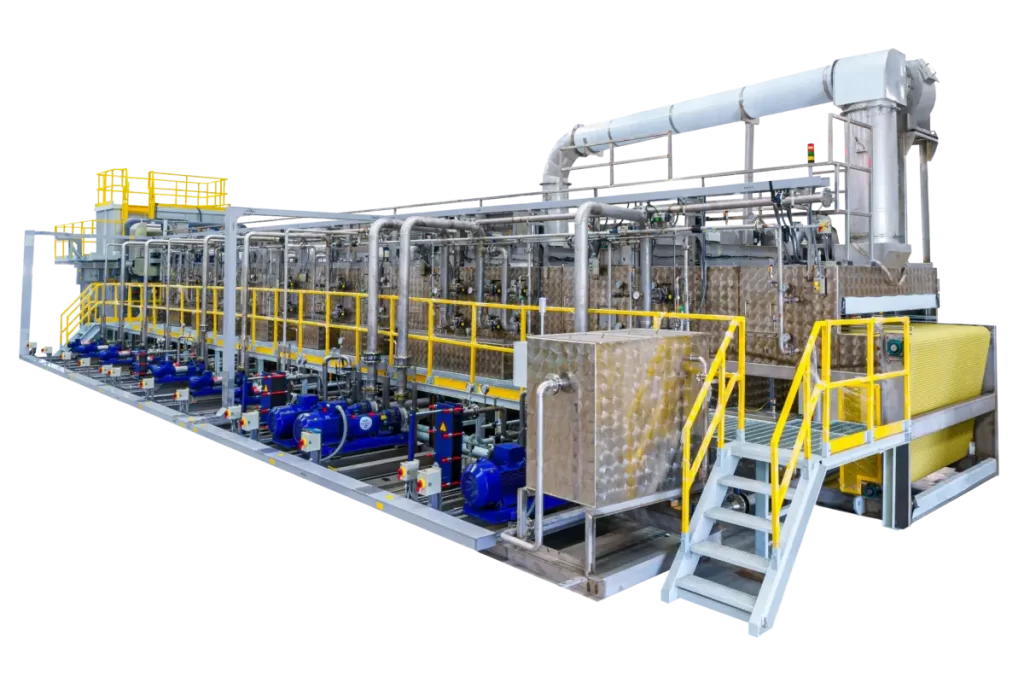

Engineered for energy efficiency, wastewater reduction and process optimization, the ARC Pacific Can Washer operates up to 6,000 cpm.

Dry-off Oven is designed for high efficiency with VFD fans, dynamic oven balance based on production conditions and premium insulation technology.

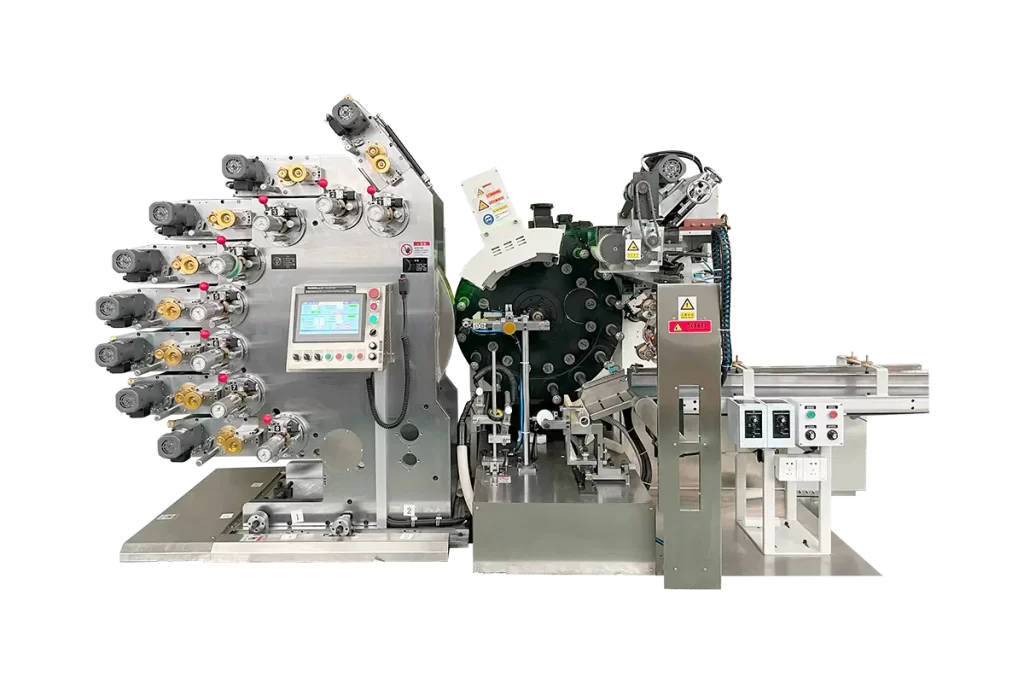

The Woolley Decorator produces high quality printed cans efficiently with continuous operating speeds up to 2,200 cpm.

The Bottom Rim Coater applies a wear-resistant coating, that facilitates superior protection to the can’s bottom rim surface.

Designed to maximize ease of operation, the Pin Oven features high accessibility, temperature uniformity, and minimized gas consumption.

Designed for uniform air flow and temperature distribution, the Internal Bake Oven cures both the interior and exterior of the can efficiently while minimizing gas consumption.

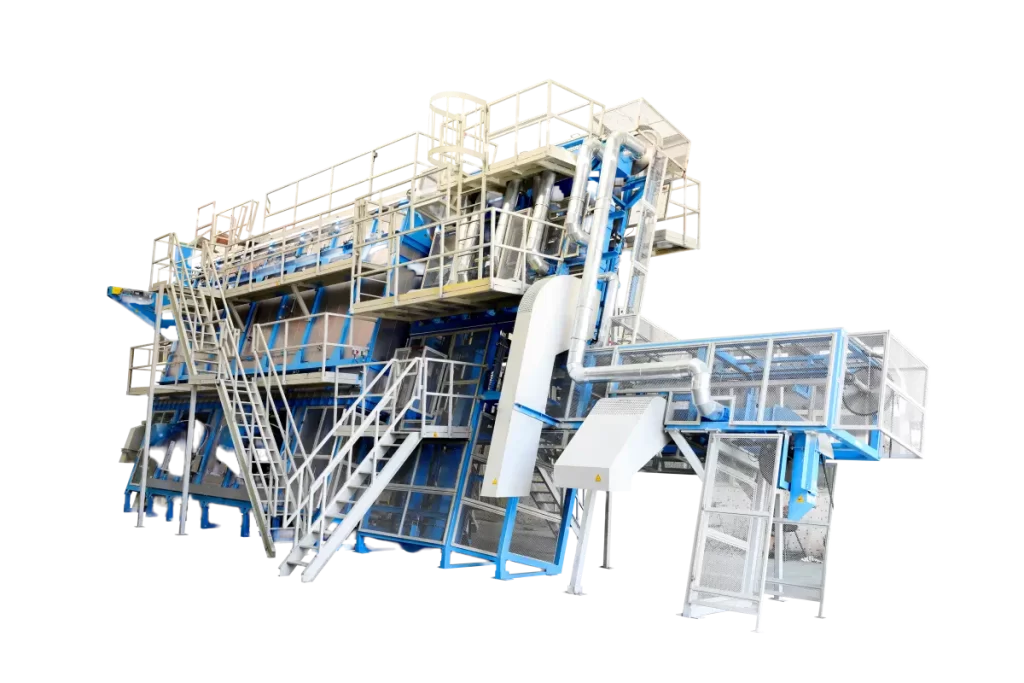

The VE Series is engineered for longevity, offering the highest cost-effective setup, continuously operating up to 3,000 cpm.

The Woolley Necker set a new standard of speed while optimizing container quality, production throughput, and return on investment.

Continuously operating up to 3,600 cpm, the Servo Woolley Necker offers the most flexibility, highest efficiencies and lowest cost of operation.

Need Help?

Ready to speak with a Woolley team member? Contact us today.

contact us