CN Necker

Can Making Machinery

CN Necker

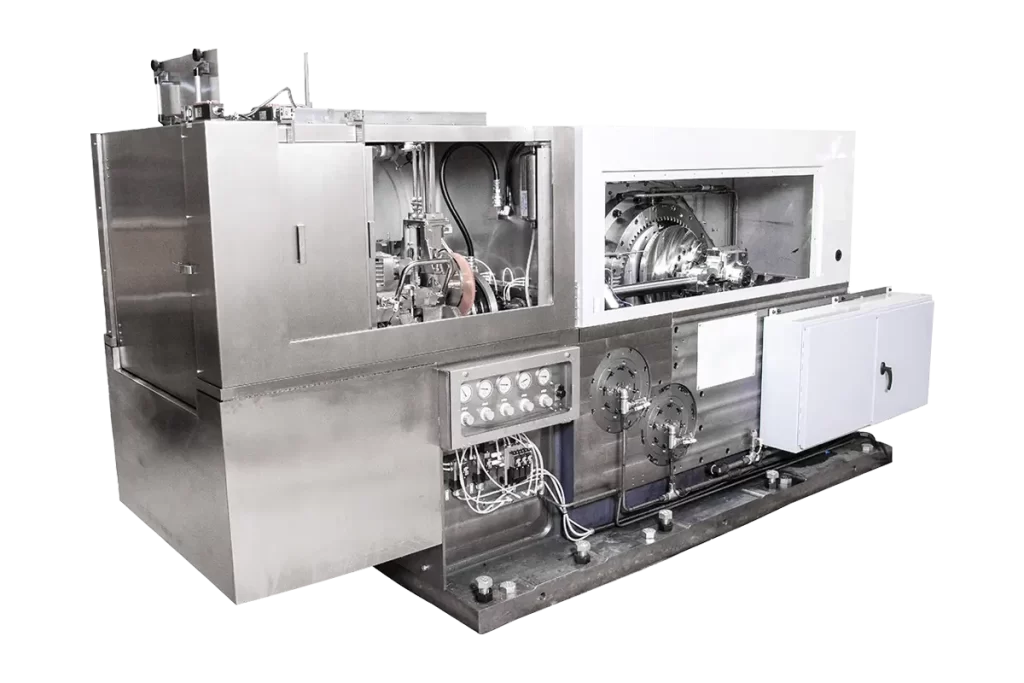

CN Series is engineered for longevity, offering the highest cost-effective setup, continuously operating up to 3,000 cpm.

Can Making Machinery

Key Benefits

With longevity and reliability at the forefront of the design process, the CN Necker series has been engineered to consistently produce high-quality cans. Available in two models, the K and SK, it is capable of producing 2,400 and 3,000 cpm, respectively. With its modular design, the CN Necker series is easy to rebuild and maintain, ensuring longevity and reliability. The machine’s turret has been standardized, streamlining operations and reducing the time required for can-size changeovers. Overall, the CN Necker series is an efficient and cost-effective solution for customers looking to produce high-quality cans.

Can Making Machinery

Features

‣ Modular Design

‣ Engineered for Longevity

‣ Interchangeable Parts

‣ Quick-Change Height and Diameter Adjustment

‣ Pocket-to-Pocket Correlation

‣ Advanced Face Seal Manifold to Minimize Air Consumption

‣ Hard Chrome-plated Can Guides and Starwheels

‣ Optional Intermediate Infeeds

‣ Can Neck Lubricator

Can Making Machinery

Introduce

The machine offers various features, including flanging, reforming, reprofiling, light tester, and inspection modules. It’s also equipped with an Intelligent Manufacturing System (IMS) and High-Speed Selective Sorter that provide dynamic quality control and rapid sampling while troubleshooting upstream problems. The CN SK model’s spring-loaded cam followers help reduce size changeover times, increasing efficiency and cost-effectiveness. Additionally, Woolley’s Intermediate Infeed enhances flexibility and efficiency while saving equipment cost and floor space requirements

Can Making Machinery

Related Products

The Woolley Necker set a new standard of speed while optimizing container quality, production throughput, and return on investment.

Continuously operating up to 3,600 cpm, the Servo Woolley Necker offers the most flexibility, highest efficiencies and lowest cost of operation.

Utilizing a hypocycloid main drive the Woolley Bodymaker produces superior can quality with low tear-off rates, continuously operating up to 400 cpm

Need Help?

Ready to speak with a Woolley team member? Contact us today.

contact us