Can Washer

Can Making Machinery

Can Washer

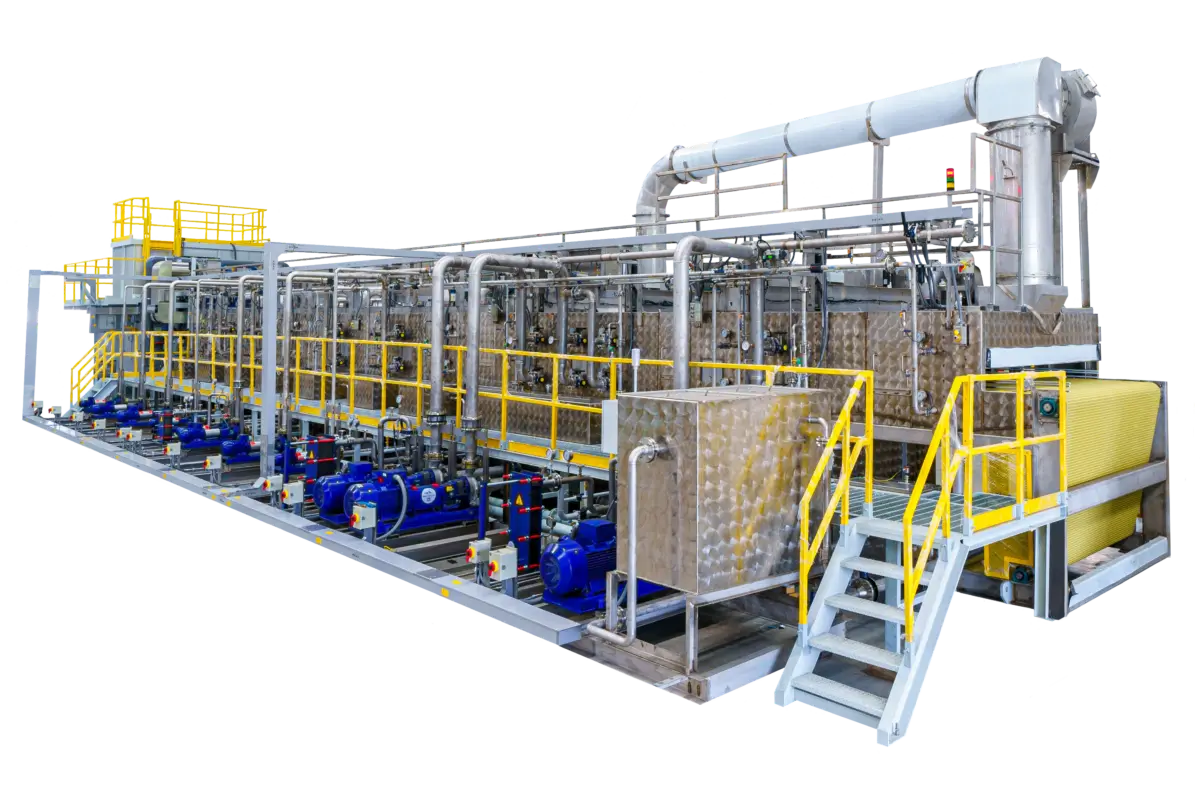

Engineered for energy efficiency, wastewater reduction and process optimization, the Woolley Can Washer operates up to 6,000 cpm.

Can Making Machinery

Key Benefits

The Woolley Can Washer is engineered for energy efficiency, wastewater reduction and process optimization. With a stainless-steel base frame and structure, the Washer features eight stages, each with cleaning or rinsing functions. Designed to remove oils, lubricants, and remaining debris from the bodymaking and trimming process on the interior and exterior of the cans, the Can Washer operates up to 6,000 cpm. Engineered to be variable speed allowing for operators to better control process efficiency by shutting off rinsers and adjusting pump volume, saving on energy costs. Can size changeovers can be easily achieved through the automated height adjustment for the hold-down, which can be operated via the HMI.

The eight-stage process includes Pre-rinsing, Pre-washing, Washing, Rinse Cycle 1, Coating Treatment, Rinse Cycle 2, De-ionizing, and Mobility Enhancing. Cans are moved through the machine on a main conveyor belt system, an upgradable feature, which reduces lifetime wear and electrostatic buildup between the can and conveyor, facilitating a better can handling surface. The pumps and blow off systems, which spray water and blow air during the process stages are fitted with VFDs and allow for further power and water use reduction and process optimization. Additionally, the VFDs on the blow-off system have been precisely engineered to remove the additional water build up on the dome of the can while only consuming the minimum power requirements. During operation, the tank water level is monitored via sensors which send real-time updates to the HMI.

Can Making Machinery

Features

‣ VFD’s for all Pumps and Blow-offs

‣ Tank Water Level Monitor

‣ Main Conveyor Belt Upgrade

‣ Automated Height Adjustment for Hold-Downs

‣ Adjustable Side Guards

‣ Dual speed capabilities

‣ Oil Coalescer

‣ Energy Management System

‣ Quick Change Risers

‣ Up to 6,000 cpm

Can Making Machinery

How it Works

The initial stages include pre-rinsing and pre-washing where most oils, lubricants, and coolants are removed, preparing the cans for the washing stages. An efficient pre-wash will help lower usage of chemicals in the later washing processes as well as increase the washing efficiency. During the washing stage, chemicals are applied to remove organic and inorganic impurities helping to prepare the can for the treatment stage. The oil coalescer recycles wastewater from the pre-wash and washing stages to help reduce water consumption and maximize process optimization.

In the first rinse cycle the can is sprayed clean to remove the chemicals from the previous washing stage. A chemical is applied to the cans during the treatment stage which helps prevent corrosion and discoloration of the aluminum during the pasteurization process. The can is rinsed for a final cycle to remove any remaining chemicals. As the cans move forward in the Washer, they are de-ionized to remove the inorganic salts from the cans surface. In the final stage a mobility enhancer is applied which prepares the surface of the can with a roughness facilitating better printing results from the Decorator. Once they finish the eight, and final stage, the cans are vacuum transferred to the dry-off oven.

Can Making Machinery

Related Products

Dry-off Oven is designed for high efficiency with VFD fans, dynamic oven balance based on production conditions and premium insulation technology.

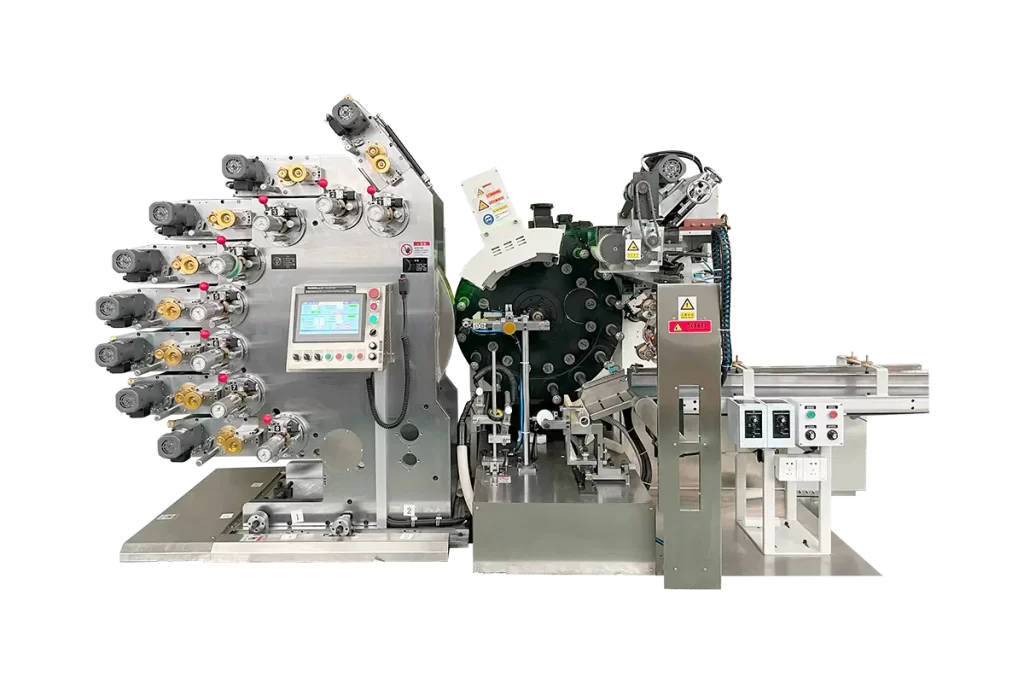

The Woolley Decorator produces high quality printed cans efficiently with continuous operating speeds up to 2,200 cpm.

The Bottom Rim Coater applies a wear-resistant coating, that facilitates superior protection to the can’s bottom rim surface.

Need Help?

Ready to speak with a Woolley team member? Contact us today.

contact us